Why does the HY Chemical dispersant 5027H sometimes cause gelation when used in dispersion coatings?

Is it due to insufficient dispersing force, or is it caused by an incompatible reaction with the customer's system?

After studying the customer's formulation and process, a problem was discovered: the customer added the film-forming agent during the grinding process, causing the film-forming agent to be poorly dispersed in the emulsion due to the high dispersion temperature when the emulsion was added. This resulted in the film-forming agent clumping the emulsion together, which led to flocculation and ultimately, gelation.

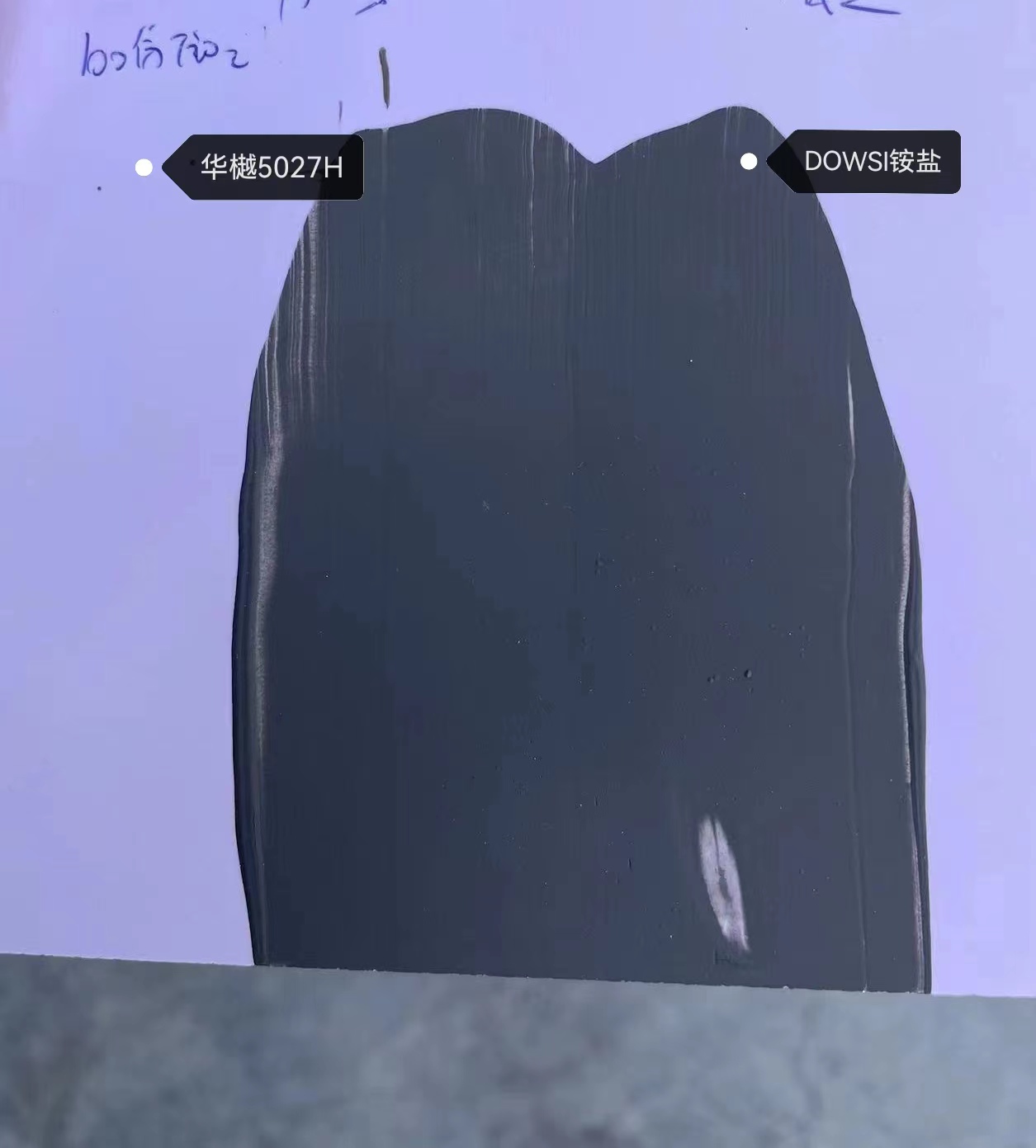

Therefore, the film-forming agent should always be added slowly and after the dispersion process. Suitable processes can produce latex paints with good whiteness and opacity. The picture below shows latex paint produced using 5027H, with the same type and amount of black pigment added to the paint. The blackness of the paint using 5027H is significantly reduced, indicating that the covering power of the latex paint produced using 5027H is significantly better than that of competing products.